PolyLevel (Polyurethane Foam) vs Mudjacking — Complete Guide for New Jersey Homeowners

Polyurethane foam lifting, often called PolyLevel or polyjacking, is a fast and low-profile way to raise sunken concrete. Mudjacking, the traditional cement slurry method, remains the most durable, cost-effective, and repairable solution for many driveways, sidewalks, patios, and commercial slabs in the United States, especially New Jersey and Eastern Pennsylvania, where we serve. We explain how each method works, compare costs, durability, and environmental impact, and show real case studies so you can decide with confidence.

Who this guide is for

If you are a homeowner, property manager, or business owner with sunken or uneven concrete, this guide is for you. We wrote it so you can quickly understand the methods, make an informed choice, and get the right work done for your property in Cherry Hill, Morristown, and Freehold, or anywhere in New Jersey, along with Pennsylvania areas such as Allentown, Bethlehem, and Bucks County.

How PolyLevel (polyurethane foam) works

PolyLevel foam is an expandable polymer made from high-density polyurethane. It is created when two chemical components are forced together under pressure: a blend of polyols (organic hydroxyl compounds) and isocyanates. This reaction is exothermic, meaning it generates heat as it expands into a foam that fills voids and pushes concrete slabs back into place.

While it may sound like a high-tech solution, it is important to understand what happens behind the scenes. Both polyols and isocyanates come from crude oil, which is a non-renewable resource. These raw materials are not locally sourced. They are manufactured in chemical plants, transported to refineries, and then shipped again before reaching a property. Each step, from drilling oil to refining and long-distance shipping, adds cost and environmental impact compared with the natural, quarry-based materials used in mudjacking.

Another challenge is practicality. PolyLevel is a two-component system that must be heated and carefully mixed on-site to work properly. The equipment requires extra energy, and when outdoor temperatures fall below 40°F, the foam does not perform reliably. This means cold-weather repairs are often impossible, making it unsuitable for many emergencies during New Jersey winters.

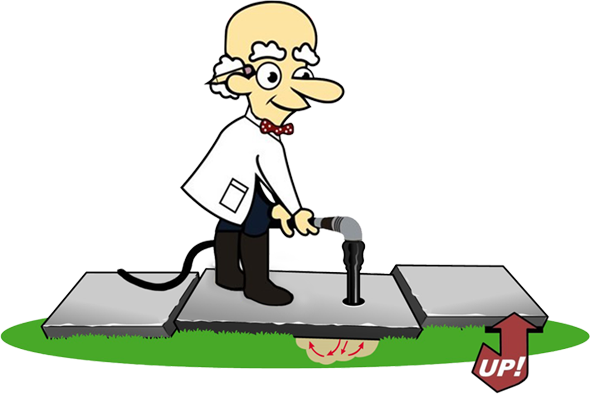

Polyurethane foam concrete lifting is a modern technique where a two-part polyurethane mixture is injected under a concrete slab through small holes. The material reacts and expands, filling voids and pushing the slab back to the desired level.

Keypoints

People like PolyLevel because it is fast, low profile, and often clean. Typical use cases include residential driveways, sidewalks, garage slabs, and areas where digging or heavy equipment access is limited.

One of the most important concerns is the chemical makeup of polyurethane foam. Polyfoam contains isocyanates, compounds that are recognized as toxic substances by both the EPA and OSHA. According to OSHA’s official guidance on isocyanates, they are classified as potential human carcinogens and have been shown to cause cancer in animals. Beyond long-term health risks, isocyanates are also known to cause respiratory irritation, asthma, and skin sensitization for workers exposed during installation.

When to choose PolyLevel

Choose PolyLevel when:

PolyLevel shines at small to medium residential jobs where speed and minimal disruption are top priorities but it comes with a lot of risk in the long run. Polyurethane foam also carries flammability risks because of the heat released during its chemical reaction.

In one documented case, a foam filler caused a fire at a meat-processing factory, leading to lawsuits against the contractors and sellers involved. Situations like this highlight why fire safety must be considered when evaluating foam injection.

Pros and cons of PolyLevel

| Pros | Cons |

|---|---|

| Smaller holes | Cost. Polyurethane products are often more expensive per square foot |

| Lightweight | Repairability. If you need to remove foam later, it is difficult and can damage the slab. |

| Long-term performance. While performance is generally good, polyurethane formulations vary and long-term data over decades is more limited than for cement-based systems. | |

| Environmental concerns. Polyurethane is a synthetic material and requires special handling at disposal. It is flammable and toxic. | |

| Less compressive strength |

How Mudjacking works

Mudjacking, also called slabjacking, uses a cement-based grout mixture to lift and stabilize sunken concrete. The grout is made from common construction materials such as Portland cement, fly ash, fine aggregates, water, and sometimes small amounts of admixtures to adjust strength or flow. The exact proportions can be adjusted depending on the needs of the job, which makes the process flexible and effective for a wide range of situations.

One of the biggest advantages of mudjacking is that it uses materials that are produced locally and sourced from abundant natural resources. Unlike polyfoam, which relies on petroleum-based chemicals that must be refined and shipped long distances, the components of mudjacking grout are available in almost every region. This means less environmental impact, lower costs, and a more sustainable repair method.

Just like concrete itself, mudjacking grout is durable, recyclable, and safe to handle. Once pumped beneath the slab, the grout fills voids, stabilizes the soil, and raises the concrete back into place. Because it cures into a solid, load-bearing base, it provides long-term stability that stands up to heavy use.

In short, mudjacking works by using natural, dependable, and widely available materials to restore concrete slabs at a fraction of the cost of replacement, with results that can last for decades.

Keypoints

Mudjacking works well for heavier slabs, large lifts, and commercial applications where durability and long-term performance matter. Just like concrete itself, the mudjacking grout is durable, recyclable, and safe to handle. Once it’s pumped beneath the slab, it fills voids, stabilizes the soil, and raises the concrete back into position. As the material cures, it transforms into a solid, load-bearing base capable of supporting heavy loads, high traffic, and years of use.

Mudjacking offers a smart, sustainable, and cost-effective solution to uneven or sunken concrete. By using natural and dependable materials, it restores your concrete slabs at a fraction of the cost of replacement — providing a level, stable surface that can last for decades.

When to choose Mudjacking

Choose Mudjacking when:

For many homeowners and businesses, mudjacking remains the best balance of cost, durability, and long-term value.

Pros and cons of MudJacking

| Pros | Cons |

|---|---|

| Durable and proven. Mudjacking has been used for decades with predictable results | Slightly larger holes |

| Cost-effective for large lifts and heavier slabs. | Longer reopen times while the grout cures, especially for vehicular movements. |

| Materials are simple and compatible with concrete repairs. | Occasional equipment accessibility challenges. |

| Easier to rework or add more material later if further settling occurs. | |

| It is an all-natural, locally sourced product with no recyclability or flammability issues. | |

| Higher compressive strength |

Side-by-side Comparison Table

Note: All numbers are typical ranges. Actual costs and timelines vary by contractor, project size, and site conditions. Always request a written estimate and ask for references.

| Feature | PolyLevel (Polyurethane) | Mudjacking (Cement Slurry) |

|---|---|---|

| Hole size | Small 5/8 inch | 1 inch |

| Cure time / reopen | Minutes to hours for light use | Typically ready for foot traffic immediately or 24 hours for vehicle traffic |

| Material Weight added | Very light | Heavier, stronger product with long-term durability |

| Typical uses | Small lifts, tight spaces, interiors | Large lifts, heavy slabs, long-term durability |

| Lifespan | Manufacturer-dependen | Proven long-term performance when properly installed |

| Cost (typical) | Often higher per sq ft for small jobs | Usually lower cost for large or deep lifts |

| Repairability | Harder to remove if future work is needed | Easier to rework, compatible with concrete repairs |

| Water resistance | Less permeable to water infiltration | A properly mixed mudjacking grout is not susceptible to washout |

| Environmental considerations | There are recyclability issues. It sticks to the concrete and concrete recycling facilities consider it a contaminant; disposal harder | Cement-based; more familiar landfill handling |

Mudjacking and New Jersey and Eastern Pennsylvania conditions

— why it matters

New Jersey covers diverse soils and climates. From coastal sand in Atlantic City to clay and mixed glacial tills in Eastern PA, northern and central NJ, soil conditions affect slab behavior.

Here are practical reasons mudjacking is often the better fit:

That said, there are locations in NJ where PolyLevel is a strong choice. We evaluate each property to recommend the right solution.

Case Study 1: Sunken Pool Deck, Holmdel, NJ

Problem

A pool deck in Holmdel had settled unevenly, creating tripping hazards and an unattractive appearance around the swimming area. The homeowner worried about both safety and resale value.

Why Mudjacking

Replacing the entire pool deck would have been extremely expensive and disruptive. Mudjacking provided a fast, cost-effective solution that restored safety and appearance without tearing out concrete.

Outcome

The slabs were lifted back to their original height, patched, and blended to look seamless. The homeowner was able to enjoy the pool area again within days, while saving thousands compared to a replacement or polyurethane quote.

Case Study 2: Sunken Walkway, Branchburg, NJ

Problem

In Branchburg, a homeowner’s front walkway had sunk, creating a six-inch offset and allowing rainwater to pool near the entrance. This not only posed a trip hazard but also risked water damage to the home.

Why Mudjacking

Because the slabs were still in good condition structurally, mudjacking was the logical choice. It provided a stable, long-lasting lift while avoiding the cost of replacement.

Outcome

The walkway was raised to level, restoring proper drainage and safe entry to the home. The homeowner was relieved to avoid an expensive replacement and loved how the patched areas blended with the existing concrete.

Case Study 3: Sunken Patio, Ringoes, NJ

Problem

A family in Ringoes had a backyard patio that had sunk by 4 inches unevenly over the years, making outdoor gatherings uncomfortable and the surface unsafe.

Why Mudjacking

Polyurethane would have been costlier and unnecessary for this type of load. Mudjacking created a dense, supportive base that stabilized the patio for long-term use while keeping costs manageable.

Outcome

The patio was leveled, the holes patched, and the area restored to full use. The homeowner was able to enjoy their outdoor space again without the expense of replacement.

Cost considerations

and value

Cost depends on project size, location, access, and the chosen method. Here are general points to consider:

Always get at least two written estimates and ask for a breakdown of materials, hole size, labor, and warranties.

Safety, Sustainability, and the Truth About Polyfoam vs. Mudjacking

Over the last 15 years, the polyurethane foam industry has spent millions promoting foam injection as a “superior alternative” to mudjacking. What often goes unsaid is that this marketing push benefits foam manufacturers because they can control the supply chain and keep contractor costs high. In contrast, mudjacking uses cement-based materials sourced locally from quarries, making it harder for manufacturers to monopolize.

We have objectively considered adding polyurethane foam to our services (our equipment supplier even sells foam injection systems). However, documented cases raise serious concerns. For instance, Academic studies highlight risks, including toxic off-gassing and exothermic reactions that can result in spontaneous combustion after placement.

Why mudjacking grouts are safer and more sustainable than polyfoam

Customizable performance

Polyurethane foam always cures to the same fixed strength. Mudjacking grout can be tailored to soil conditions by adjusting cement, sand, and water ratios. This flexibility makes it effective across New Jersey’s wide range of soil types.

Recyclability

Mudjacking material can be crushed and recycled alongside concrete slabs for use as fill or aggregate. Polyfoam, being a plastic, must be removed before recycling. This adds cost, energy, and waste.

Worker and environmental safety

Mudjacking grouts are non-flammable and do not release toxic fumes. Foam, on the other hand, is made from chemicals that can release noxious gases. The injection process also generates heat that has been linked to spontaneous fires.

Soil bearing capacity

While mudjacking grout is heavier, this added mass is generally insignificant compared to the natural load-bearing capacity of soils. The benefit is a dense, stable base that better resists washout and seasonal cycles.

The bottom line

Both foam and grout can lift concrete, but only mudjacking offers a method that is adaptable, recyclable, safe for workers, and proven for decades. For homeowners looking at the full lifecycle value of their property, mudjacking remains the smarter, more sustainable choice.

Common

Misconceptions

Myth: PolyLevel is always better because it is new.

Truth: New technology brings useful options, but it does not automatically replace traditional methods. PolyLevel shines for fast, low-impact jobs and spaces where small holes are critical.

For heavy traffic areas, large lifts, or jobs where future rework is likely, traditional mudjacking still offers predictable, proven performance.

Myth: Mudjacking will always cause more settlement because it’s heavy.

Truth: Properly mixed and installed mudjacking slurry forms a dense, supportive base beneath the slab. A competent technician assesses soil conditions first. In rare cases with extremely soft soils, supplemental stabilization or a different method may be recommended.

Myth: If the contractor uses foam it means they’re more modern and therefore better.

Truth: A contractor’s choice of material should be driven by the job requirements and site conditions, not marketing. The best contractors offer both options, explain tradeoffs, and recommend the method that gives the best long-term value for your property.

Myth: Once you use poly foam you never need to touch the slab again.

Truth: No permanent repair is maintenance-free. Polyurethane can perform extremely well, but all systems face environmental stresses and shifting soils. Also, foam-based repairs are harder to modify later if the slab requires re-leveling or replacement.

Myth: All polyurethane systems are the same.

Truth: Formulations, injection equipment, and technician skill vary. Some products are engineered for specific soil types or load conditions. That variation means that blanket claims about “poly always works” or “poly never works” are misleading.

How We Work — What to Expect When You Call Us

At Concrete Chiropractor, getting your concrete lifted or leveled is simple and hassle-free. You don’t need to schedule a site visit or wait around for inspections. Instead, all you do is send us clear photos of the problem areas. From those images, we provide a free online estimate that outlines the cost, the recommended approach, and the expected results.

With over 25 years of experience and thousands of successful jobs completed across New Jersey and Eastern Pennsylvania, we’ve seen just about every concrete issue imaginable. That experience allows us to quickly identify whether mudjacking or another solution is best for your property, and we’ll explain our reasoning in plain language so you understand exactly what you’re paying for.

Once you approve the estimate, we schedule the work and carry it out professionally. Every project is completed with attention to safety, cleanliness, and precision. We document the job with before-and-after photos so you can clearly see the transformation. And because we stand behind our work, all projects include a written warranty for your peace of mind.

We proudly serve homeowners and businesses throughout New Jersey, from Newark and Jersey City to Hoboken, Elizabeth, Edison, Princeton, and surrounding towns. Many of our happy clients are right in your neighborhood, and we’re always glad to share testimonials that prove the quality of our service.

Choosing the Right Contractor

When you’re comparing companies, don’t just focus on price. The right contractor should have deep local experience, a proven track record, and the ability to clearly explain what they’re doing and why. At Concrete Chiropractor, our reputation comes from decades of hands-on work in New Jersey soils, thousands of successful lifts, and countless satisfied customers. We believe that kind of trust is worth more than a flashy sales pitch.

FAQs

Final recommendation

We believe in educating property owners. PolyLevel is a valuable tool in the right situations, especially for small, fast, low-impact repairs where minimal downtime matters. For many homeowners and businesses, mudjacking remains the best overall choice because of its proven durability, cost-effectiveness for larger repairs, and ease of future rework.

If you would like, we can schedule a free inspection over the phone to evaluate your slab and give a clear recommendation tailored to your property. Call us or contact us online to arrange a no-obligation evaluation and estimate. We will show you photo documentation, provide a clear written estimate, and explain why mudjacking might be the smartest long-term choice for your New Jersey or Eastern Pennsylvania property.