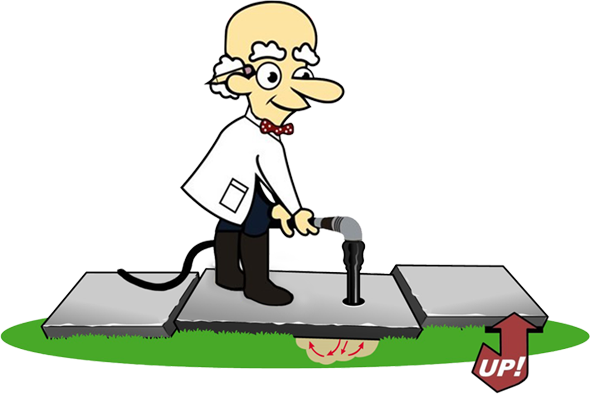

How the Concrete Poly Foam Leveling Process Works

Concrete Leveling With Foam, or method of raising concrete with foam is also often referred to as “poly jacking

To address concrete settlement due to loose soils, small holes are drilled through your concrete surfaces. A high-density polyurethane foam is then injected to fills voids. It then lifts the concrete slab or slabs. Lastly, the drill holes are then patched with a cement.

While concrete lifting foam diy may be possible, it requires the proper equipment and experience and is not recommended for the average home or property owner.

Mudjacking Versus Poly Foam Concrete Leveling – Fact vs. Fiction

If you came here because you are interested in concrete leveling methods to raise your sunken concrete slab, you came to the right place. With over 40 years of experience, the Concrete Chiropractor® is here to help you make the right choice when searching concrete foam jacking near me. We spent years researching this concrete repair method, and although we could offer it we decided NOT to offer it in our service lineup for concrete raising.

While there may be some very limited raising concrete slabs with foam circumstances where foam may be applied in commercial repair settings, we do not recommend its use in 99% of the applications.

The risk, liability, and recyclability issues, along with costs associated with injecting foam, offset any minimal benefit to “you,” the customer.

Below are some reasons why we strongly suggest you use a Mudjacking cement grout to raise your concrete, not Poly Foam.

Concrete leveling using poly foam is a newer process added to concrete raising. A man-made, petroleum-based product, chemically known as poly isocyanate, is injected through a 5/8” hole. The foam then expands, raising the settled or sinking concrete slab.

This differs from the eighty- plus year old, original process called mudjacking. Mudjacking uses an earth-based material such as sand, clay, or limestone.

These natural products are mixed into a Portland cement grout. This grout is then injected through holes drilled through a concrete slab roughly the size of a quarter, or

The concrete patio, pool deck, floor, or sidewalk slab will then float back to it’s original position.

Advantages of Mud-Jacking Grout for Use in Slab Leveling White Paper

Poly leveling foam is marketed based on claims that the product offers several benefits over traditional Mudjacking. Civil and environmental engineers have scientifically studied these claims. When the poly foam product claims are evaluated through mathematical and scientific investigation, they not only lack validation, but the product has detrimental health and environmental effects such as flammability, toxicity, and recyclability. This NJIT study titled “Advantages of Mudjacking Grout for Use in Slab Leveling” explains the benefits and risks of the two concrete raising products. Here are a few statements from their study on these three topics:

Flammability:

Mud-jacking grouts are non-flammable and do not produce toxic gasses and are generally safe to the surrounding environment. Polyurethane foam based leveling systems, however, have experienced spontaneous combustion during and shortly after application. Most notably, a project in Vancouver, BC, Canada where slabs outside of a building were leveled with the polyfoam material. The foam material, which produces heat during the expansion process, caught fire underneath the slabs. The fire released noxious fumes that shut down the area around the slabs and blocked people from using the buildings around it for a week. The fire has resulted in multiple lawsuits and claims ].

Toxicity:

Isocyanates are a group of highly reactive chemicals and are irritants to the eyes and respiratory system. Contact with skin can also cause significant inflammation. Severe asthma attacks resulting in death have been known to occur from exposure to isocyanates.

Recyclability:

Conversely, the use of polyfoam materials as a leveling system restricts the recyclability of concrete slabs. Polyfoam must be completely removed before a concrete slab can be recycled, which can be quite difficult as it sticks to the bottom of the slab where it connects with the slab to lift it into place.

Additional equipment and manpower are required on site to remove the polyfoam from the concrete slab, increasing the cost of recycling the slabs. The cost increase associated with cleaning out the polyfoam makes it much more likely that a slab lifted with polyfoam will be landfilled, rather than recycled.

The traditional method of concrete repair in NJ and nationwide for sinking concrete, with it’s over 80-year history it, has been the time-proven method known as mudjacking, the only way to raise concrete without the unknown history of Poly leveling, or Polyurethane foam concrete raising and void filling.

Here at Concrete Chiropractor, we are experienced specialists and one of the original companies in the field of mudjacking and slabjacking in NJ.

Concrete Chiropractor® is the leader in the field of concrete lifting in NJ and concrete raising in NJ.

As part of our dedication and obligation to level sinking concrete, we have attended many shows, such as World of Concrete, to stay abreast of new technology that would significantly change the settling concrete repair field. The latest option is known as the Poly leveling foam concrete raising.

If we feel there was a new method that would better serve the customer or it was a feasible mudjacking alternative, we would not hesitate to add it to our existing method of concrete leveling. While others have jumped on this bandwagon of “selling” poly leveling, at this time, we do not see a true advantage in the majority of applications to polyurethane injection grouting over the traditional, time-proven methods of concrete repair. We back our method with our long-standing reputation and our personal guarantee.

If you are looking to raise concrete safely at a reasonable price with a well-known company that will stand behind you, guarantee its work, and have an excellent reputation, then you need to call Concrete Chiropractor.

Some Polyfoam claims are:

Poly foam is lightweight and will not cause settlement like Mudjacking grout

Facts show that the main cause of concrete settlement is due to disturbed soils during initial home and building construction and not due to weight. Main building structures far exceed the weight of concrete slabs on grade and are footed on undisturbed soils. These soils generally do not settle. However, concrete slabs that surround a structure such as concrete pool decks, garage floors, patios, porches, and walkways that are prone to settlement failure.

A know fact is the difference of 100 pounds per cubic foot between Mudjacking grout and poly foam is insignificant as undisturbed soils generally support 1500 to 3000 pounds per square foot.

Poly foam is environmentally friendly

Poly-Isocyanate, the chemical name for poly foam is a two-part product consisting of a part A and part B. When mixed there is a chemical reaction. This reaction is known to off gas and generate heat. This poly foam product which has been used for concrete raising has a history of flammability and self-combustion. There are documented cases in which these poly foam fires have resulted in health-related lawsuits and the National Institute of Safety and Health, NIOSH, requires the use of a respirator and gloves along with skin and face protection. The CDC has stated that poly foam has a history of reactions including death.

In addition to separation costs and added recycling costs during concrete replacement, poly foam cannot be accepted at concrete recycling facilities.

Poly foam products have been shown to come with a long-term environmental impact. The use of poly products such as plastic bags, bottles, Styrofoam’s have resulted in plastic reduction and bans. Further use of these products is predicted to come at a much higher financial and environmental cost going forward.

Poly foam does not wash out like mudjacking grout

It is a known fact that poly foam products do no biodegrade and can take hundreds of years to break down. However, tests have shown that a properly mixed and tested Mudjacking grout with Portland cement can withstand long term water resistance. Cements have a time-proven history of durability against weather dating back thousands of years.

The actual concern with all concrete leveling repairs regardless of the product used is to correct all water issues. A down spout discharging next to a slab, roof water, or a lack of drainage from poorly pitched grade will not only result in washout of any base soils but can also increase the possibility of frost damage in colder climates.

In The News

10 lawsuits filed over 2010 Vancouver chemical fire

A chemical incident that shut down blocks of downtown Vancouver two years ago and saw hundreds of residents evacuated from the Electra building at Burrard and Nelson streets has resulted in a flurry of lawsuits.