Concrete Floor Leveling & Repair

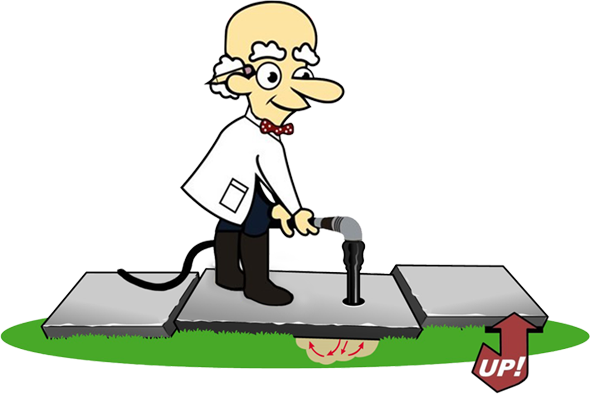

Uneven and sunken concrete floors in homes affect your home’s functionality and harm home value and resale. Concrete Chiropractor’s team of experts has decades of experience as a concrete leveler. We can restore your home floor’s stability, support, and appearance with our environmentally friendly method.

Cause Concrete Home Floor Settlement

Certain areas are known for soil stability issues, but the main cause of settlement for inside concrete floors is a loose or uncompacted soil subbase during the initial construction of your home. As your soil settles, the concrete slab that is resting on it settles with it. A void or air space between a concrete slab and the supporting soil is often present, causing the concrete floor to bridge without support.

Once the soil base settlement process under your floor has finished after several years, the voids can be filled and the floor raised with our concrete leveling process, leaving you with a long-lasting repair.

Easy and Affordable Concrete Floor Repair

Concrete Chiropractor’s team of professionals has decades of experience in uneven or damaged concrete floor repair using our time-proven system. We can level your floor, saving you money on costly, disruptive concrete replacements. Concrete Chiropractor provides expert concrete leveling knowledge along with specialized concrete equipment to make long-lasting floor repairs for homeowners.

If uneven or sunken concrete floors have you down, our solution can have your concrete floor ready to use the same day!

Why Use the Concrete Chiropractor Team for Your Concrete Floor Leveling Project?

Learn More at The Concrete Chiropractor

Find more answers by experts to your questions related to concrete leveling repair in our online articles.

Five Common DIY Concrete Pouring Mistakes to Avoid

Let’s face it, when you’re a homeowner, there’s no bett ...

Facts About Garage Floor Sinking and Repair

Cracked and sunken garage floors are more than just an ...

What to Do When Your Garage Floor Cracks

When you’re faced with the unfortunate situation of a s ...

Cure Your Concrete Settlement

You do not have to live with a higher trip and fall liability or lower curb appeal and home value caused by sinking concrete. With Concrete Chiropractor, “Mother Nature May Shift It, But We Can Lift It!”TM.

Click the link below to request a professional evaluation from our industry experts!